How To Scale From 100 to 1,000 Orders/Day with a China Fulfillment Partner

How To Scale From 100 to 1,000 Orders/Day with a China Fulfillment Partner

Stuck at 100 orders a day?

Ads are working, traffic looks fine, but growth feels risky?

I hear this a lot.

The jump from 100 to 1,000 orders per day isn’t about finding a new product.

It’s about whether your fulfillment system can handle pressure without breaking.

This is where a China fulfillment partner becomes a real growth lever—not just a cost decision.

Let me walk you through what actually changes when stores scale successfully.

Why Scaling Feels Harder Than Starting

At 100 orders a day, most stores are still flexible.

Manual order checks

Supplier chats on WeChat

Fixing problems one by one

It works… until it doesn’t.

At 1,000 orders a day:

Small delays turn into hundreds of complaints

One stock mistake creates thousands in refunds

Shipping instability destroys ad performance

The issue isn’t effort.

It’s that manual systems don’t scale.

What Breaks First When Order Volume Explodes

Before talking solutions, let’s be honest about the weak points.

Inventory Visibility

Most fast-growing stores don’t really know:

What’s actually in stock

Which SKUs are aging

Which products generate most of the profit

At low volume, guessing is survivable.

At scale, guessing is expensive.

Supplier Bottlenecks

Factories move at factory speed, not ad speed.

Delayed updates

Partial production

Missed timelines

Without a buffer, your growth depends on too many “ifs.”

Shipping Instability

Shipping costs and delivery times change constantly.

Carrier adjustments

Peak-season surcharges

Line suspensions

When shipping becomes unpredictable, customers notice—and churn.

Why a China Fulfillment Partner Changes the Equation

A real China fulfillment partner isn’t just storage space.

They act as:

An inventory buffer

A process manager

A shipping stabilizer

Most importantly, they separate growth from operational stress.

That separation is what allows you to scale calmly.

Step 1: Centralize Inventory Before You Push Volume

You can’t scale what you can’t see.

With proper fulfillment integration, you get:

Real-time inventory sync

SKU-level tracking

Clear stock alerts

This lets you:

Pause ads before stockouts

Scale winning products with confidence

Reduce dead inventory

Visibility creates control.

Control makes growth repeatable.

Step 2: Let Marketing Move Fast While Fulfillment Stays Stable

Here’s a mindset shift most sellers need.

Marketing should move quickly.

Fulfillment should be boring.

A strong China fulfillment partner:

Holds safety stock

Ships daily on fixed schedules

Absorbs supplier delays

This lets you increase ad spend without checking inventory every hour.

That peace of mind matters more than most people expect 🙂

Step 3: Standardize Packaging and Pick-Pack Rules

Customization feels good—until volume hits.

At scale, every extra decision costs time.

What works better:

Standard box sizes

Pre-approved inserts

Clear labeling rules

Standardization improves:

Packing speed

Error rates

Shipping consistency

Your fulfillment partner should help design this, not just execute it.

Step 4: Secure Shipping Lines Before You Actually Need Them

Many sellers look for shipping solutions only after delays start.

That’s already too late.

A China fulfillment partner helps you:

Test multiple routes early

Match SKUs to optimal lines

Switch lanes without operational shock

This matters most during:

Q1

Chinese New Year

Carrier policy changes

Stable shipping protects both margins and customer trust.

A Real Scaling Story

One Shopify brand selling home accessories came to us at about 120 orders/day.

A viral campaign pushed them to 700+ orders almost overnight.

Their supplier couldn’t keep up.

Orders piled up. Refunds spiked. Support tickets exploded.

They moved inventory into a China fulfillment setup.

Within weeks:

Orders stabilized around 900/day

Delivery time averaged 7–9 days

Customer complaints dropped significantly

Same products.

Same ads.

Different infrastructure.

That’s what fulfillment scale looks like.

Step 5: Plan for Peaks, Not Averages

Most stores plan fulfillment based on normal days.

Scaling stores plan for worst days.

You should know:

Maximum daily processing capacity

Overtime handling options

Holiday staffing plans

If your fulfillment partner can’t answer clearly, scaling will be painful.

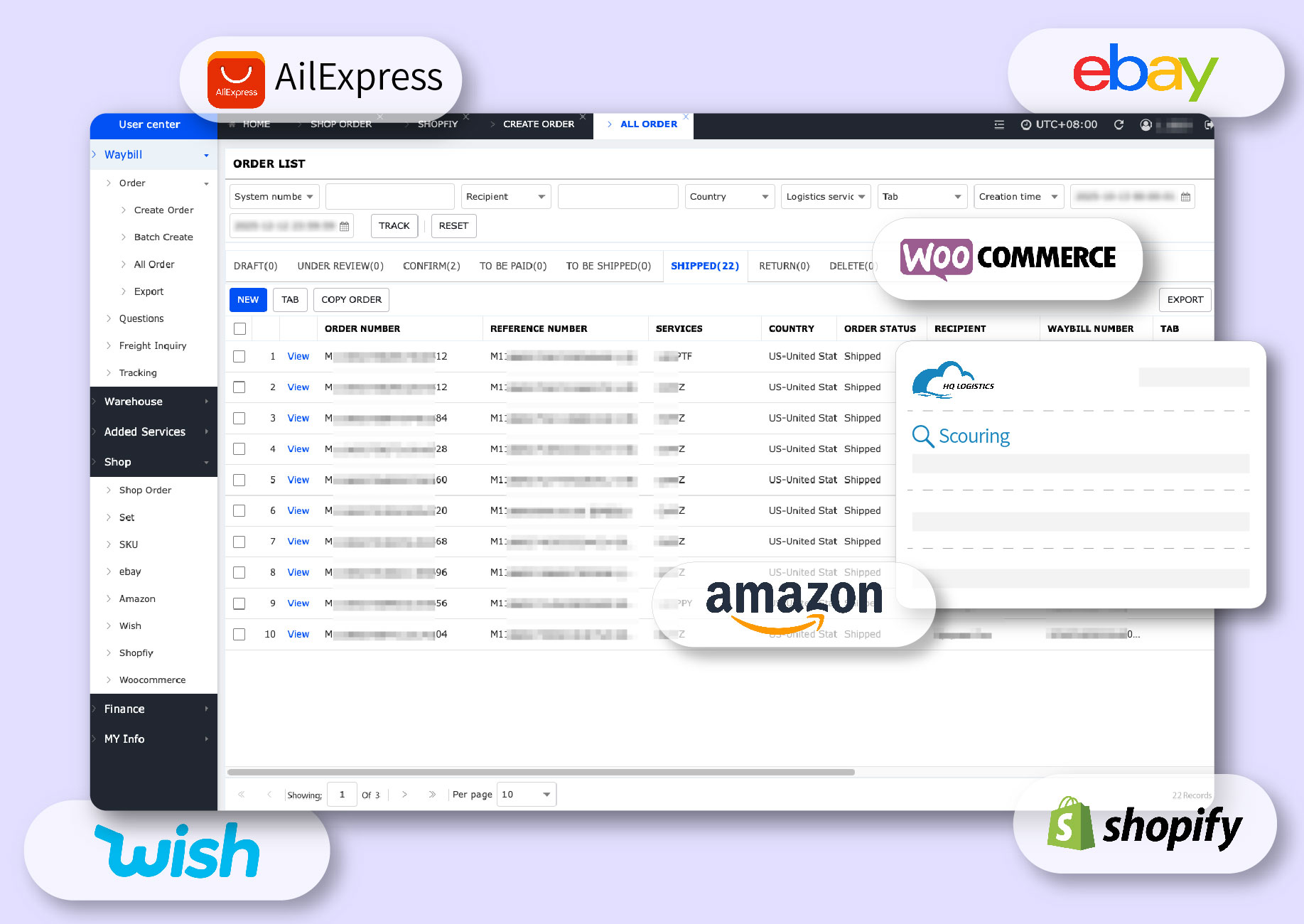

Step 6: Remove Manual Touchpoints Completely

Manual processes hide risk.

At scale, you want:

Automatic order sync from Shopify

Real-time tracking updates

Auto inventory deductions

If someone is exporting spreadsheets, growth will slow sooner or later.

Automation isn’t a luxury.

It’s basic infrastructure.

Step 7: Use Data to Decide What Deserves Scale

Not every product should grow.

Fulfillment data helps you see:

Order velocity by SKU

Inventory aging

Fulfillment cost per unit

This allows smarter decisions:

Push ads on high-margin SKUs

Bundle slow movers

Drop underperformers early

Scaling is about focus, not volume.

Common Mistakes Sellers Make When Scaling

A few patterns show up again and again:

Scaling ads before fixing operations

Relying on a single supplier

Choosing shipping purely on price

Ignoring fulfillment SLAs

Growth rewards systems, not shortcuts.

FAQ

When should I switch to a China fulfillment partner?

When you’re consistently around 80–100 orders/day.

That’s the safe point to prepare for scale.

Will fulfillment in China slow delivery times?

No—if done right, delivery often becomes more stable and predictable.

Do I need large inventory to scale?

No. You need planned inventory, not excess inventory.

Can one fulfillment partner handle multiple suppliers?

Yes. Good partners consolidate suppliers into one system.

What’s the biggest scaling mistake?

Scaling ads before fixing fulfillment infrastructure.

Final Thoughts

Scaling from 100 to 1,000 orders per day isn’t magic.

It’s about:

Visibility

Stability

Predictability

A reliable China fulfillment partner lets you grow without panic.

When fulfillment becomes boring,

scaling becomes possible.

And that’s exactly where you want to be.