Chinese New Year Fulfillment: How to Ship Without Losing Sales

Chinese New Year Fulfillment: How to Ship Without Losing Sales

Struggling with delayed orders every January?

Stocked up, but shipping still stopped?

Or worse—ran out of inventory mid-holiday? 😬

I’ve seen Chinese New Year break good fulfillment plans.

This is my straight-up guide to Chinese New Year Fulfillment—what actually happens, and how brands should prepare.

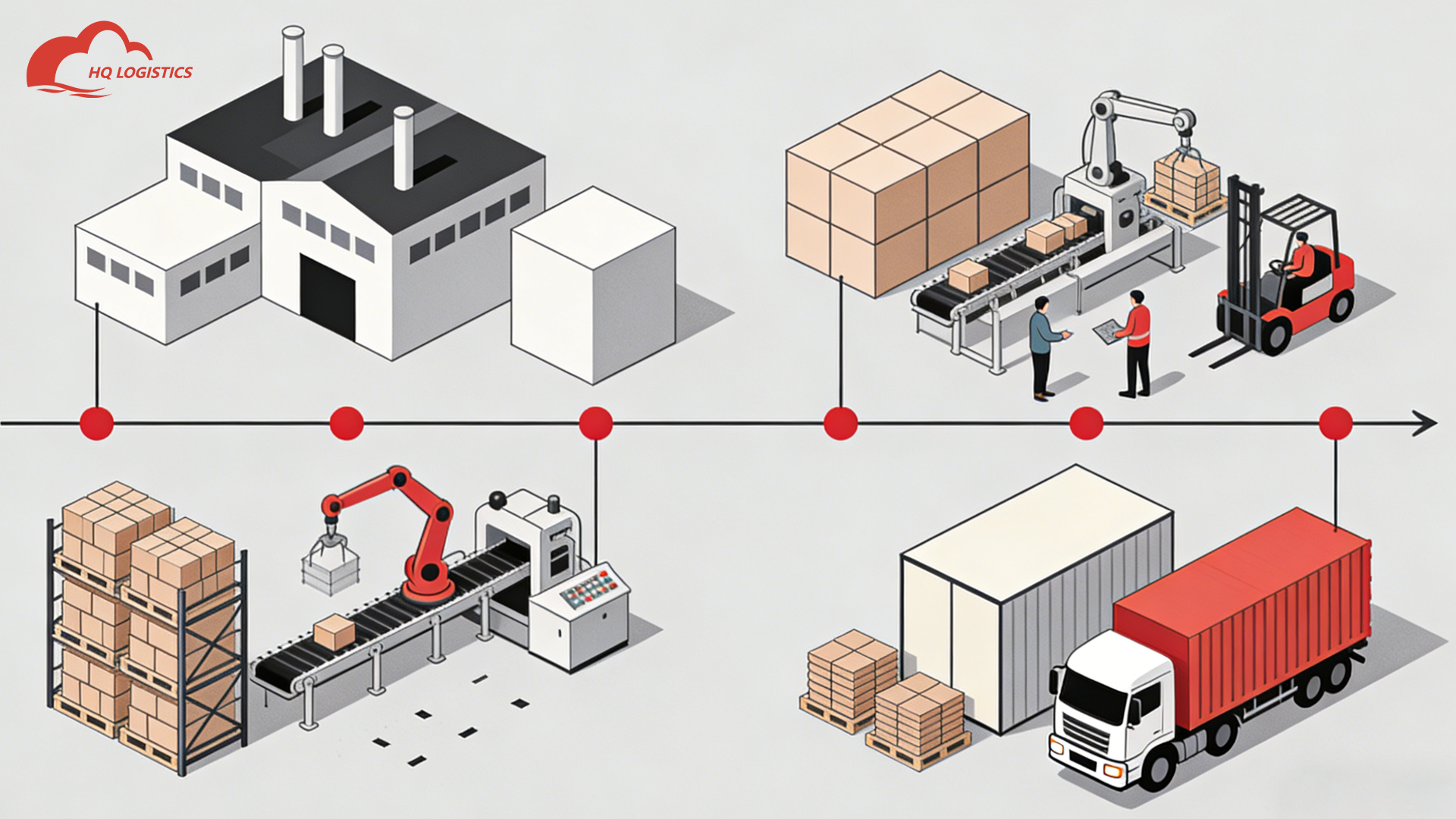

What Chinese New Year Fulfillment Really Means

Let’s clear one thing up first.

Chinese New Year is not:

-

A 3-day holiday

-

A short factory break

-

A “business as usual” period

It’s a supply chain slowdown that affects:

-

Factories

-

Warehouses

-

Trucking

-

Customs

-

Carriers

Even when factories reopen, fulfillment doesn’t snap back instantly.

That gap is where brands lose money.

How Chinese New Year Impacts Fulfillment

Factory shutdowns start earlier than you think

Most factories:

-

Stop production 7–14 days before Chinese New Year

-

Resume gradually after the holiday

Workers don’t all return on day one.

Result:

Production delay + backlog pressure.

Shipping capacity tightens fast

During Chinese New Year:

-

Fewer flights

-

Limited trucking

-

Higher express prices 🚀

Fast lanes recover first.

Cheap lanes lag behind.

This matters for fulfillment timing.

Warehouses stay open—but inventory doesn’t move

Many China fulfillment centers:

-

Remain operational

-

Have limited inbound replenishment

So if stock runs out,

you can’t fix it quickly.

Common Chinese New Year Fulfillment Mistakes

I see the same errors every year.

Mistake 1: Stocking too late

Some brands stock:

-

2 weeks before Chinese New Year

That’s risky.

If inbound misses the cutoff,

inventory simply doesn’t arrive in time.

Mistake 2: Relying on one fulfillment lane

Using only:

-

One carrier

-

One service level

Means no flexibility when delays hit.

Mistake 3: Keeping normal delivery promises

Customers don’t care about Chinese New Year.

They care about their order.

If expectations aren’t reset:

-

Refunds increase

-

Chargebacks follow

A Real Story From a Seller Chat ☕

One seller told me:

“We stocked enough inventory, but still missed orders.”

The issue?

-

Inventory was ready

-

But inbound shipping arrived late

-

Warehouse never received it before Chinese New Year

This year we changed:

-

Earlier inbound cutoff

-

Smaller, earlier stock build

-

Backup fulfillment lanes

Result:

No stockouts.

No panic upgrades.

Planning beat volume.

What a Good Chinese New Year Fulfillment Plan Looks Like

Here’s what I recommend.

1. Stock earlier, not heavier

Instead of overstocking:

-

Build inventory 4–6 weeks ahead

-

Focus on best-selling SKUs

-

Freeze slow movers

This reduces risk and cash pressure.

2. Split fulfillment lanes

Don’t put all orders on one route.

Smart setup:

-

Economy lanes for non-urgent orders

-

Fast lanes for priority SKUs

Flexibility matters most during Chinese New Year.

3. Adjust delivery promises early

Before Chinese New Year starts:

-

Update delivery timelines

-

Add holiday notices

-

Set clear expectations at checkout

Honesty beats speed during this period.

China Fulfillment vs Local Fulfillment During Chinese New Year

Some brands ask:

“Should I move everything local?”

Not always.

China fulfillment during Chinese New Year

-

Lower cost

-

Higher delay risk

Local fulfillment

-

Faster delivery

-

Higher inventory commitment

Best solution?

A hybrid model:

-

Keep testing SKUs in China

-

Move proven sellers local before Chinese New Year

FAQs: Chinese New Year Fulfillment

1. How early should I prepare for Chinese New Year fulfillment?

At least 6–8 weeks ahead.

2. Is shipping completely stopped during Chinese New Year?

No, but capacity is limited and inconsistent.

3. Are fast lanes worth it during Chinese New Year?

Yes—for time-sensitive orders only.

4. Should I pause ads during Chinese New Year?

Not necessarily. Adjust delivery promises instead.

5. When does fulfillment fully normalize after Chinese New Year?

Usually 2–3 weeks after factories reopen.

Final Take

Chinese New Year Fulfillment isn’t about speed.

It’s about anticipation.

Brands that win:

-

Stock earlier

-

Plan backup lanes

-

Communicate clearly

Brands that lose:

-

React late

-

Assume normal timelines

-

Hope for the best

Hope is not a fulfillment strategy.